Basalt Sand Making

Release time:

2025-07-17

As an important building material,basalt has the characteristics of strong compressive resistance,low crushing value,strong corrosion resistance,and good asphalt adhesion.It has been widely used in airport runways,highways,high-speed railways,urban construction and other fields.It is an internationally recognized high-quality roadbed material.

Basalt sand making characteristics

As an important building material,basalt has the characteristics of strong compressive resistance,low crushing value,strong corrosion resistance,and good asphalt adhesion.It has been widely used in airport runways,highways,high-speed railways,urban construction and other fields.It is an internationally recognized high-quality roadbed material.

In the process flow of basalt sand production line,full sand making and semi-sand making production processes can be adopted.Which specific process to adopt can be designed according to customer needs.

Basalt sand making process

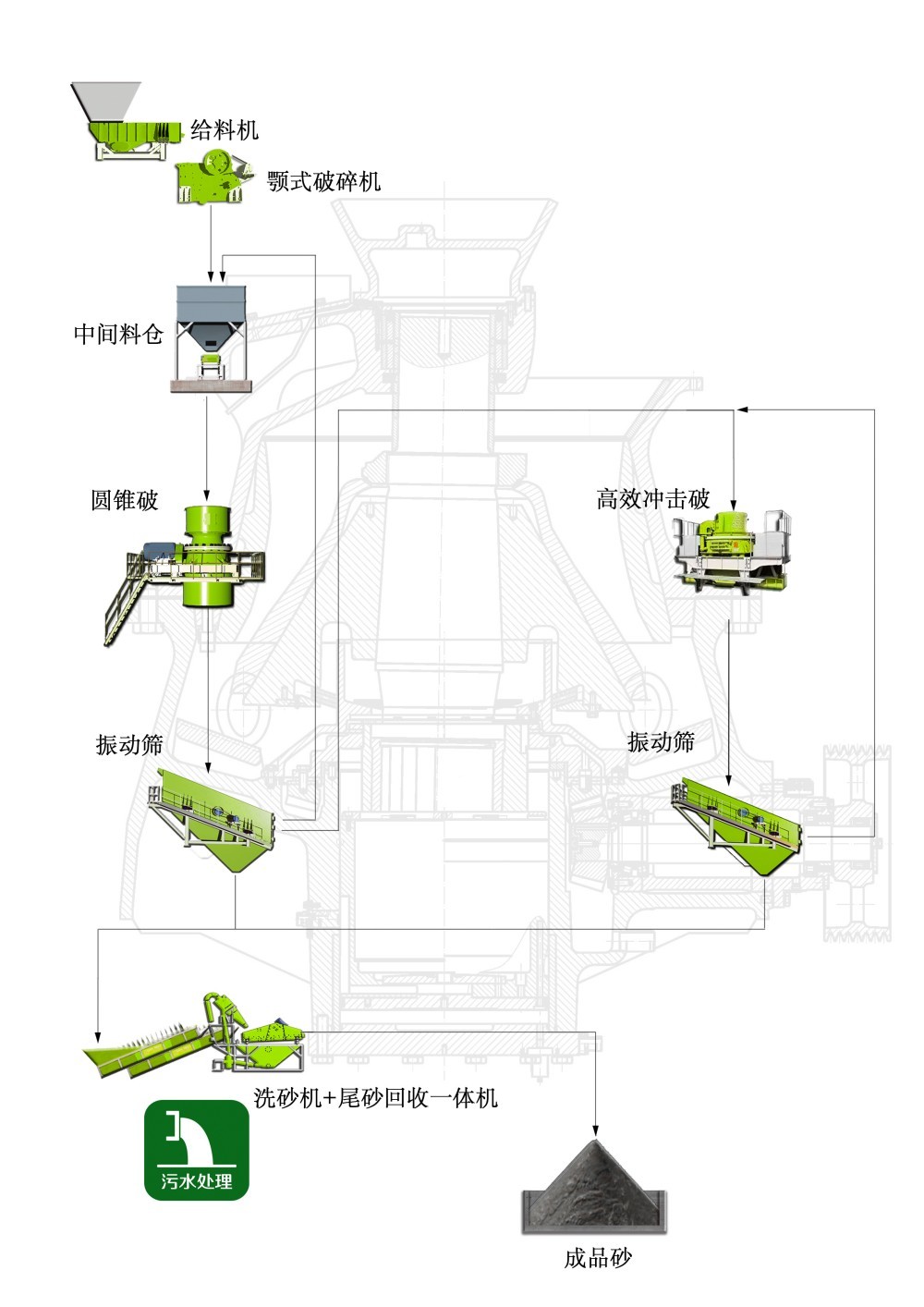

In the process flow of basalt sand production line,full sand making and semi-sand making production processes can be adopted.Which specific process to adopt can be designed according to customer needs.This article recommends the process flow of basalt sand production line mainly for full sand making process.That is:jaw crusher+cone crusher+high-efficiency impact crusher+circular vibrating screen.Auxiliary equipment can be added according to specific customer needs:sand and gravel powder separator,wet mixer,dust removal equipment,feeding system,dust collection device,etc.

Basalt sand production line

With the continuous depletion of natural river sand and the requirements for high-grade concrete pouring,the demand for fine machine-made sand is increasing.Fine machine-made sand has become a new development direction and profit growth point for various sand and gravel yards,creating more value for customers while continuously improving the quality of sand and gravel.Based on years of practical experience,Dahongli Machinery has explored a complete set of machine-made sand production process to meet customers'stringent requirements for fine machine-made sand.

In the process of basalt sand production line,full sand making and semi-sand making production processes can be used.The specific process can be designed according to customer needs.This article recommends the process of basalt sand production line mainly for full sand making process.That is:jaw crusher+cone crusher+high-efficiency impact crusher+circular vibrating screen.Auxiliary equipment can be added according to specific customer needs:sand and stone powder separator,wet mixer,dust removal equipment,feeding system,dust collection device,etc.

Process description:

The vibrating feeder sends the large-size natural raw stone into the jaw crusher for coarse crushing;the coarsely crushed material is sent to the intermediate silo by the conveyor belt,and then sent to the cone crusher for crushing,and then transported to the vibrating sorting screen by the belt conveyor for screening.The stone that meets the particle size is sent to the high-efficiency sand making machine for sand making,and the material that does not meet the particle size is returned to the cone crusher through the conveyor belt for re-crushing;the material coming out of the high-efficiency sand making machine must also be screened by the vibrating sorting screen,and the material that does not meet the particle size needs to be returned to the sand making machine through the conveyor for re-crushing;the material that meets the particle size passes through the sand washing machine and then passes through the tailing sand recovery integrated machine,and is transported to the finished product warehouse by the finished product conveyor belt for storage;the sewage from the production line enters the sewage treatment system for recycling.

The specific process can also be configured differently according to different sites and different stones.

Process characteristics:

Dahongli Machinery High-efficiency Impact Crusher,as a high-efficiency sand making equipment,has excellent shaping and sand making effects.The particle size of the crushed machine sand is reasonably matched,which can meet the strict requirements of high-grade concrete pouring for machine sand.The multi-stage sand making design can achieve the effects of semi-sand making and full sand making.

Previous

Previous

With decades of experience in the mining and sandstone crushing field, the company has developed a full range of products that represent the advanced level of the industry.

Contact Us

Email:dahongli95@gmail.com

Tel:+8618980910282

WhatsApp:+8618980910282

Address: No.399 Daan Road, Dayi County, Chengdu, Sichuan, China