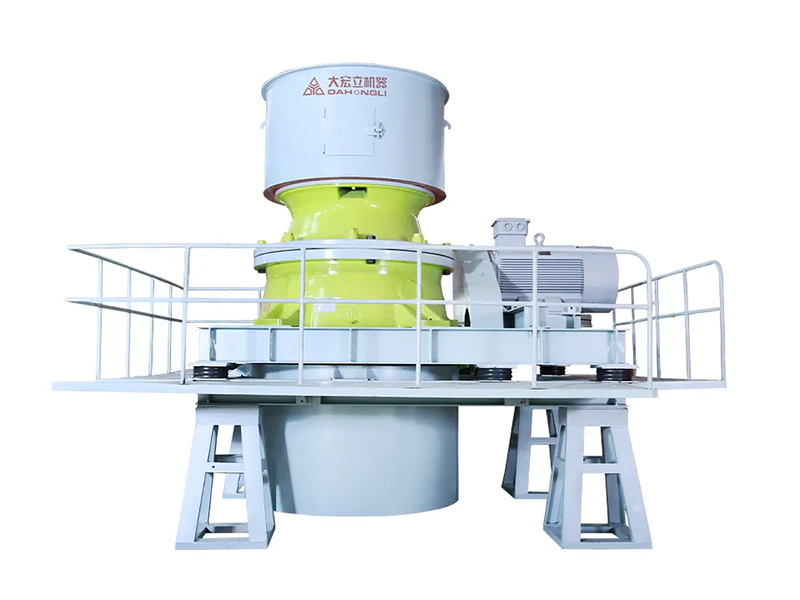

Model 300 Eco-Friendly Sand&Stone Crushing Plant

Product Description

The Model 300 Eco-Friendly Sand&Stone Crushing Plant adopts highly modular,integrated and systematic process design,integrating scattered crushing,screening and environmental protection equipment into one crushing plant.It greatly reduces the project floor space,civil construction,plant construction and installation time,and combines the stability of fixed crushing plant and the convenience of mobile crushing plant.It makes the construction of sand and gravel aggregate crushing line as simple and fast as purchasing a single machine.

Applicable raw materials:limestone,granite,diabase,pebbles and other materials.Suitable for materials with compressive strength of 60Mpa-300Mpa.

Scope of application:highway,railroad,hydropower,airport and other engineering projects.

Capacity range:200t/h-500t/h.

Product Advantage

Flexible Configuration

The crushing station adopts highly integrated machine hood modular design,providing strong scalability.

Each module can be flexibly matched to meet different customer needs.

Convenientinstallation

The crushing station adopts a full steel structure modular design,combining the stability of a fixed

crushing station with the convenience of a mobile station.

Convenient Transportation

The control room adopts internationally standardized transport units,facilitating easy and quick transport as a whole unit.

Green Environmental Protection

The crushing station adopts innovative air duct design,matched with dust removal or wastewater treatment systems,to meet curent national environmental protection requirements.

Cost Saving

Customers only need to complete the"three connections and one leveling"of the site,reducing costs for infrastructure construction and factory building.

Basic Parameter

Six Basic Parameter

Capacity:200-500T/H

Acreages:40%increase in land utilization

Finished product specifications:0-5mm,5-10mm,10-20mm,20-31.5mm 4 materials(optional)

Total power:600-3000kw

Feeding particle size:<750mm Modules can be matched to the raw materials

Applicable raw materials:limestone,granite,diabase,pebbles

Configuration List

| Model | Feeder | Jaw Crusher | Cone Crusher | Horizontal Screen | VSI Crusher | High Pressure Roller Mill | Dust Collector | Waste-water Treatment System | Classifier | Mixer | Fine Sand Machine | Tailings Recycling Unit | Control System | Monitoring System | Material Discharge System | Finished Product Conveyor |

| Economy Package | ● | ● | ● | ● | O | O | O | O | O | O | O | O | ● | ● | O | O |

| Standard Package | ● | ● | ● | ● | ● | O | O | O | O | O | O | O | ● | ● | O | O |

| Platinum Package | ● | ● | ● | ● | ● | ● | O | O | O | O | O | O | ● | ● | O | O |

The configuration list above is for the model 300 sand crushing plant.Customers can select according to actual needs. "●" indicates standard configuration,"O" indicates optional configuration.

The above configuration only includes the main part of the crushing station.The finished product conveyor belt will be selected according to the actual needs of the project.

Changes to the above equipment configuration will not be notified separately. The actual configuration shall prevail.

Key words:

Model 300 Eco-Friendly Sand&Stone Crushing Plant

Previous: None

Series of Products

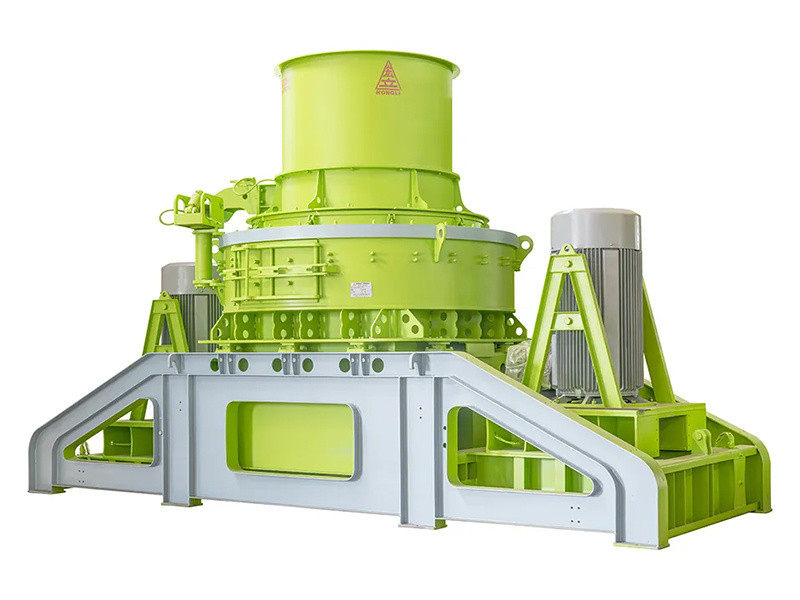

PYY Series Single Cylinder Hydralic Cone Crusher

8HL Series High-Efficiency VSI Crusher

G Series High Pressure Grinding Roller

Get a Free Quote

PLEASE LEAVE YOUR MESSAGE AND WE WILL CONTACT YOU AS SOON AS WE RECEIVE IT!

With decades of experience in the mining and sandstone crushing field, the company has developed a full range of products that represent the advanced level of the industry.

Contact Us

Email:dahongli95@gmail.com

Tel:+8618980910282

WhatsApp:+8618980910282

Address: No.399 Daan Road, Dayi County, Chengdu, Sichuan, China