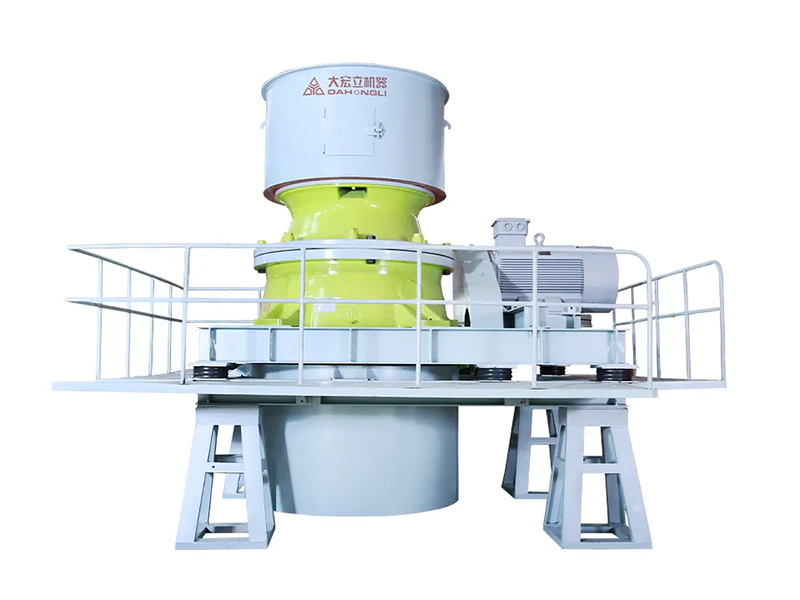

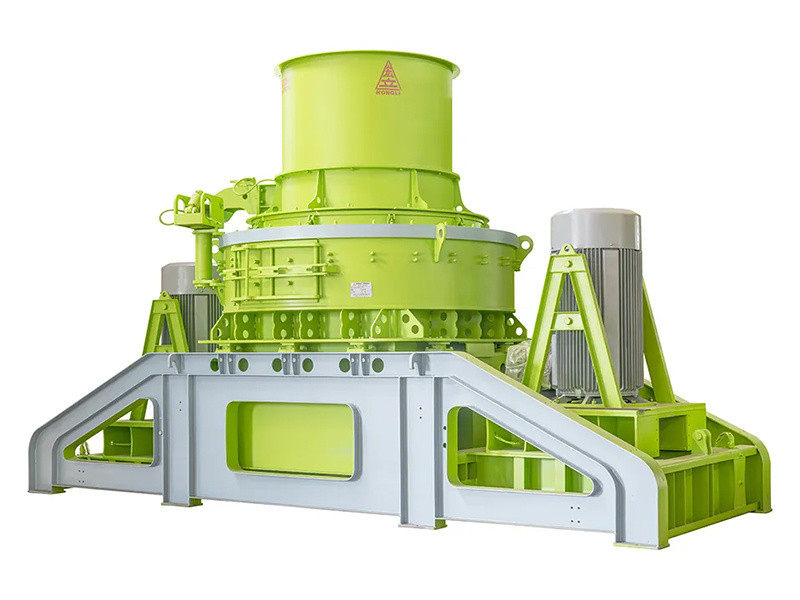

8HL Series High-Efficiency VSI Crusher

Product Description

Applicabilities

Widely used for fine crushing and forming of various ores,this device is especially suitable for secondary and fine crushing of several types of hard and brittle materials with a water content not exceeding 20%,including abrasive materials,quartz sand,limestone,cobblestone,granite,concrete aggregate,refractory materials,bauxite clinker,metallurgy slag and abrasive wear resistant materials.

Working Principle

The 8HL series high-efficiency impact crusher with waterfall flow feeding system,which introduces the second material flow into the crushing chamber with a certain controlled amount to increase the quantity or density of the material in the crushing chamber,which promotes the energy exchange between the particles.

The materials entering the crushing chamber violently collide with suspended materials and material gaskets.They collide with the materials emitted from the spinning wheels again.After repeated collision,friction,grinding and crushing,the materials are discharged through the lower discharge port.

Product Features

Hydraulic Uncovering Device

These crushers are designed with a simplified structure,making them easy to operate and install.Furthermore,the hydraulic uncovering device enhances convenience during overhauls and reduces stop time.

High Production Efficiency

Switching between“stone hitting stone”and“stone hitting iron”models increases production

efficiency,creates better granular shapes of products and reduces needle-shaped particles.

Product Gradation Control

Product gradation can be controlled by adjusting mode of crushing chamber or size of waterfall flow.

Extend Cycle Of Spare Parts

With combinational design of peripheral guard,locally worn parts can be further used after turning up and down.Hence,the combinational design prolongs replacement cycle of spare parts.

Prolong Service Life Of Triangle

Hydraulic tensioning device effectively promotes triangle tensioning of large 8HL impact crushers,increases friction,controls triangle vibration,and prolongs service life of the triangle.

Higher Recovery Rate Of Minerals

Extraordinary monomer dissociation increases recovery rate of minerals.

Options

With multiple models available,these crushers are ideal choices for sand production by fine crushing.

Technical Specifications

Model | 8HL8525 | 8HL9532 | 8HL1145 | 8HL1280 | |||||||

| Treatment capacity (t/h) | Spillover feed | 150-220 | 200-270 | 240-380 | 340-450 | 420-540 | 390-480 | 450-550 | 520-660 | 870-1360 | 1090-1700 |

| Central feed | 70-120 | 95-155 | 125-205 | 170-270 | 230-350 | 255-395 | 290-450 | 330-510 | 435-680 | 544-850 | |

| Max Feed Particle Size (mm) | Soft Material | 40 | 45 | 50 | 60 | ||||||

| Hard Material | 40 | 40 | 45 | 50 | |||||||

| Installed Power (kw) | 160 | 200 | 250 | 2x160 | 2x200 | 2x250 | 2x280 | 2x315 | 2x400 | 2x500 | |

| Driver Configuration | Single-Motor | Dual-Motor | |||||||||

| RPM (r/min) | 1200-1560 | 1100-1490 | 1000-1300 | 1070-1330 | |||||||

| Overall Weight (kg) | 15000 | 20000 | 22000 | 33000 | |||||||

The production capacity shown in this form varies with operation parameters of XHL series (RPM, spillover ratio, and variables on physical characteristics of materials). It is specific to materials with a bulk density of 1.6t/m³ which are smoothly fed and discharged.

The calculations for central feed in the above form are as follows: lower limit =linear rotor speed (75m/s) (0% waterfall flow) upper limit=linear rotor speed (60m/s) (0% waterfall flow)

The calculations for central feed in the above form are as follows: lower limit =linear rotor speed (75m/s) (30% waterfall flow) upper limit= linear rotor speed 75m/s) (100% waterfall flow)

Key words:

8HL Series High-Efficiency VSI Crusher

Previous: None

Next: None

Series of Products

PYY Series Single Cylinder Hydralic Cone Crusher

8HL Series High-Efficiency VSI Crusher

G Series High Pressure Grinding Roller

Get a Free Quote

PLEASE LEAVE YOUR MESSAGE AND WE WILL CONTACT YOU AS SOON AS WE RECEIVE IT!

With decades of experience in the mining and sandstone crushing field, the company has developed a full range of products that represent the advanced level of the industry.

Contact Us

Email:dahongli95@gmail.com

Tel:+8618980910282

WhatsApp:+8618980910282

Address: No.399 Daan Road, Dayi County, Chengdu, Sichuan, China