PCL Series - Impact Blocks

Product Description

PCL series:Includes cutting head(marked 10902),feed cone,runner plate(marked 7),and impact block.

PEV series:Includes tooth plate(marked-W 1-).

PYY series:Includes crushing wall.

TDY series:Includes drive wheel and grinding plate.

Application scenarios for accessories:

1.Aggregate production scenarios

Core applications:Various sand-making and crushing processes,such as river pebble sand-making,granite sand-making,limestone sand-making,basalt sand-making,etc.

Related accessories:The PCL series(blade heads,feed cones,flow plates,impact blocks)are commonly used in impact crushers(high-efficiency sand-making machines)for crushing and shaping sand and gravel;the PEV series tooth plates are compatible with jaw crushers for primary crushing of raw materials;the PYY series crushing walls are designed for single-cylinder hydraulic cone crushers for medium and fine crushing of sand and gravel.

2.Mineral crushing applications

Covered mineral types:Gold ore,copper ore,iron ore,manganese ore,and other metallic ores,as well as non-metallic ores.

Related components:PYY series crushing walls and PEV series tooth plates,among other components,are compatible with cone crushers and jaw crushers,serving as core components of mineral crushing production lines to crush raw ore to the desired particle size.

3.Construction Aggregate Processing Scenario

Application Process:Crushing,screening,and conveying of construction aggregates,such as concrete aggregates and roadbed aggregates.

Related Components:TDY series(drive pulleys,abrasive discs)compatible with belt conveyors ensure continuous aggregate conveying;PCL series,PYY series,and other components participate in aggregate crushing through main equipment to ensure aggregate particle size compliance.

4.Green and environmentally friendly crushing scenarios

Suitable scenarios:Modular crushing stations,green and environmentally friendly crushing plants,and other production models that prioritise environmental protection and efficiency.

Related accessories:Various accessories work in conjunction with main equipment(such as high-pressure roller mills,impact crushers,etc.)to support low-pollution,high-resource-utilisation crushing production.For example,in tailings recovery and dewatering screening processes,the stable operation of accessories ensures the continuity of green crushing processes.

How to ensure the quality of accessories

1.Leveraging the mature technological framework of host equipment

All components belong to specific host equipment series(e.g.,the PCL series corresponds to impact crushers,and the PEV series corresponds to jaw crushers).The design and production of these components must align with the technical standards of the host equipment.Such custom-developed components are typically optimised in tandem with the technological upgrades of the host equipment,ensuring compatibility with the overall performance of the machine and indirectly safeguarding operational stability.

2.Industry experience and qualifications of affiliated companies

The company has accumulated over 30 years of experience and serves over 20,000 customers,with a dedicated section for‘Honours and Qualifications’(though specific details are not displayed).In the mining machinery sector,long-term industry experience and relevant certification(such as quality management system certification)form the foundation for ensuring product quality.As core components of host equipment,accessory production processes may be integrated into a unified quality control system.

3.Service and case endorsements

The‘cases’and‘solutions’cover multiple scenarios such as construction aggregates,mineral crushing,and premium sand production.Long-term application cases of components in actual engineering projects can indirectly reflect their quality reliability—components that operate stably in various crushing and conveying production lines must withstand the challenges of high-intensity operational environments,and the accumulation of cases also demonstrates the company's control over component durability and compatibility.

Key words:

PCL Series - Impact Blocks

Previous: TDY Series-Frosted Sheet

Next: TDY Series-Main wheel

Series of Products

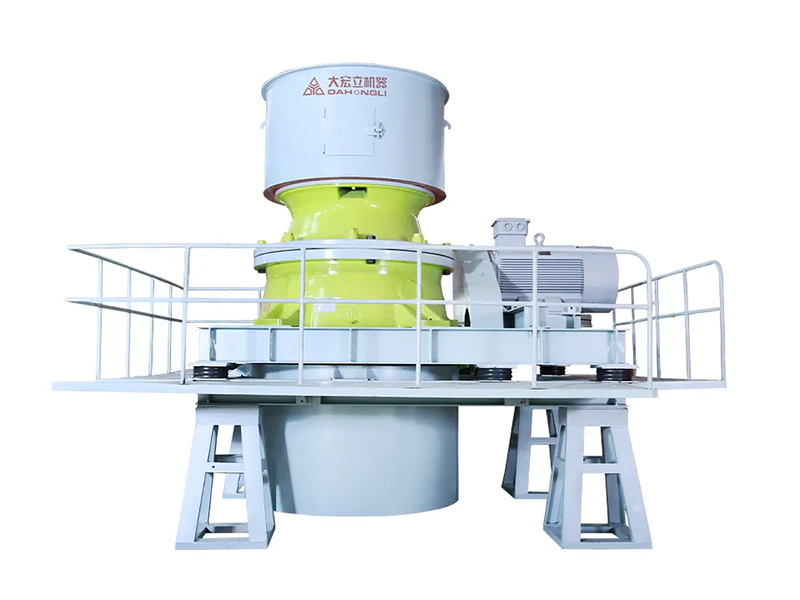

PYY Series Single Cylinder Hydralic Cone Crusher

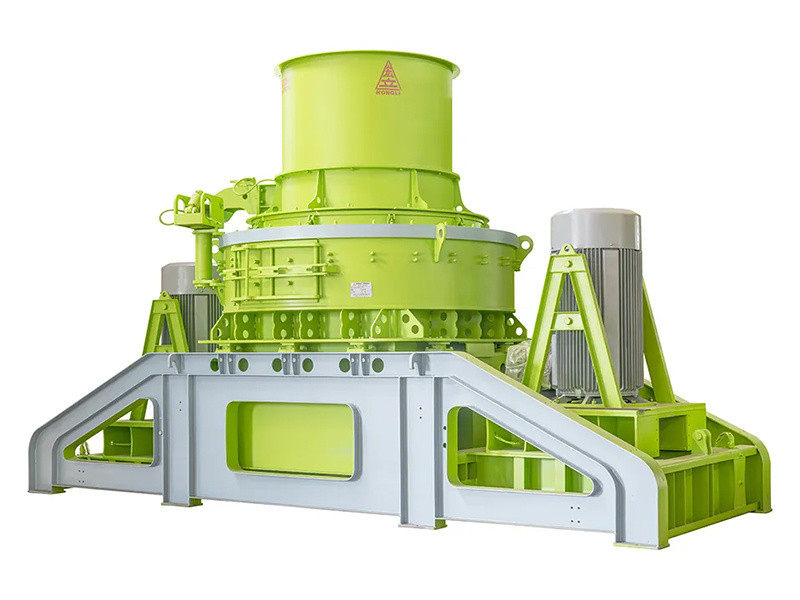

8HL Series High-Efficiency VSI Crusher

G Series High Pressure Grinding Roller

Get a Free Quote

PLEASE LEAVE YOUR MESSAGE AND WE WILL CONTACT YOU AS SOON AS WE RECEIVE IT!

With decades of experience in the mining and sandstone crushing field, the company has developed a full range of products that represent the advanced level of the industry.

Contact Us

Email:dahongli95@gmail.com

Tel:+8618980910282

WhatsApp:+8618980910282

Address: No.399 Daan Road, Dayi County, Chengdu, Sichuan, China